Flame Surface Treatment Technology

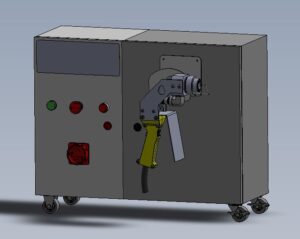

PFT-1002 Flame Treatment Unit

Fully Automated Flame Treatment Technology

THE GOLD STANDARD IN HIGH VOLUME MANUFACTURING

Modern manufacturing industries increasingly favor plastic materials due to their enhanced processability, durability, cost-effectiveness, and engineered performance. However, their application in painting or bonding processes faces challenges due to coating incompatibility, often necessitating the use of aggressive and environmentally harmful priming additives.

Flame Treatment Technology offers a solution by pre-treating the materials surface, enhancing compatibility with coatings, and promoting superior adhesion properties, all without costly environmental consequences. FTS Technologies’ flame treatment equipment provides users with a technology that reduces manufacturing costs, enhances competitiveness, improves product quality, and minimizes environmental impact.

FTS Technologies’ PFT-1002 Flame Treating System features advanced monitoring and control systems (gas analyzers), ensuring precise regulation of air/gas combustion mixtures including oxidative or reductive flame conditions, designed to maintain process integrity and safety. Critical process conditions are meticulously monitored and automatically adjusted to predefined levels, safeguarding the quality of surface treatments at all times.

Simple Flame Treatment Options

OPTIONS FOR LOWER COST, SIMPLIFIED FLAME TREATMENT APPLICATIONS

FTS Technologies has engineered an extensive range of mid-level flame treatment units that are meticulously designed without the use of gas analyzer technology. This is intended to facilitate the needs for a cost effective surface treatment solution for those applications that do not need the same level of control or sophistication associated with traditional flame treatment equipment. within high-volume injection molding facilities.

Equipment Options Available

-

-

- Basic Flame Generating Cabinet: No analyzer technology and only basic flow meter devices.

- Energy Monitoring/Laboratory Flame Treatment Unit: This highly flexible flame treatment unit utilizes gas analyzer process data to provide a very accurate flame treatment process, but does not contain any automatic process adjustments. All process parameters are manually monitored and adjusted making the unit highly flexible for a laboratory environment,

- Flow Meter Based Flame Treatment: This flame treatment product utilizes air and gas flow meters to define the process parameters. There is no gas analyzer technology and therefore no flame chemistry analysis.

-

LFT-2002 Laboratory Flame Treatment Unit

Low Capacity Flame Treatment Unit

(WITH MANUAL TREATMENT OPTIONS)

Consumer Goods; Bottle and Packaging, Collision Shop Industries

Engineered with a user-friendly design, our CIRQUALiQ flame treatment unit is your solution for enhancing adhesion and surface functionality in industries that require lower flame capacities to suit the materials being treated. Industries like consumer goods (bottles and packaging), medical, and films all require surface treatment solutions that are engineered to their specific needs.

Key Features:

-

-

- Flame Precision: The CiQ-6001 Flame Treatment Unit delivers a controlled flame that evenly treats surfaces, ensuring consistent results with every use.

- Versatile Applications: Whether you’re working with plastics, metals, or other substrates, the CiQ-6001 adapts effortlessly to your production needs, enhancing adhesion for coatings, printing, and more.

- Easy Integration: Designed with simplicity in mind, our unit seamlessly integrates into your existing production line, minimizing downtime and maximizing productivity.

- Safety First: With built-in safety features and durable construction, you can trust the CiQ-6001 to deliver reliable performance without compromise.

-

With a commitment to industry-leading expertise, cutting-edge technology, and premium products, FTS Technologies continually invests in research and innovation. This dedication ensures that our customers receive the highest level of process knowledge, enabling successful technology implementation across various applications.